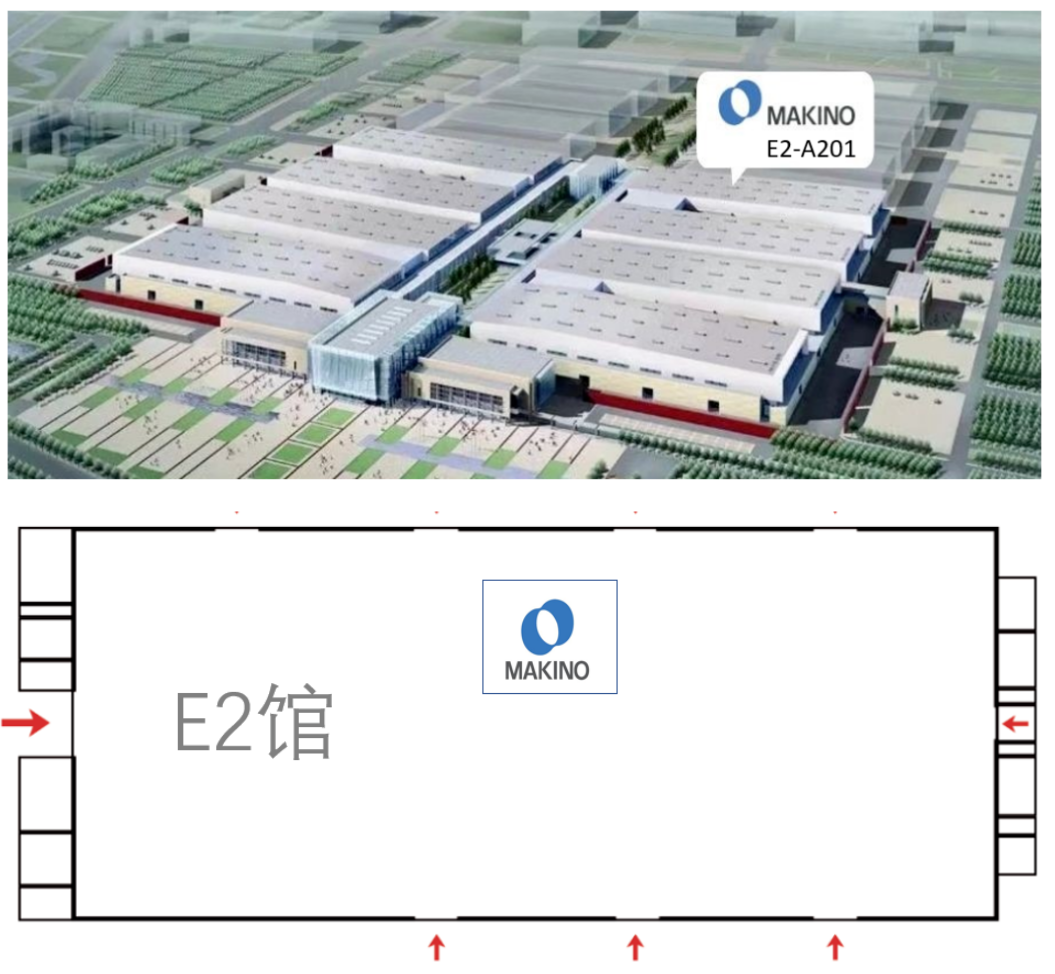

Booth number: E2-A201

invitation

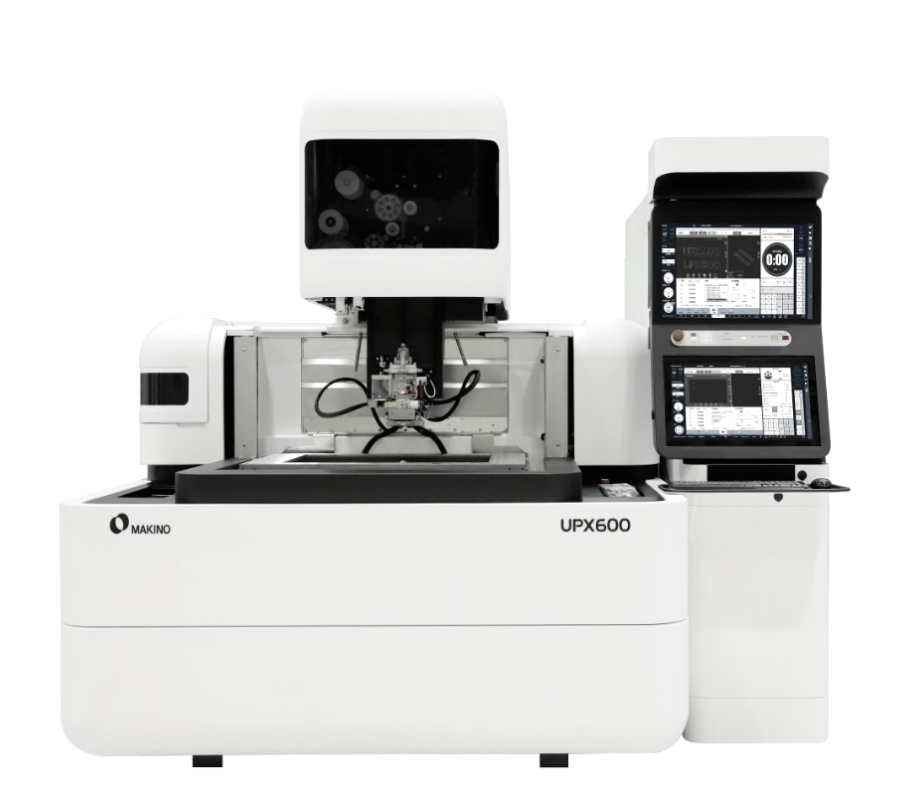

China First Exhibition

Ultra high precision wire cutting discharge machining machine UPX600

The surface finish of machining seven knives reaches Ra0.05 μ M

FSC ultra high precision adjustment, position accuracy full stroke ± 0.002mm

Ultra high stability, multi cavity mold core irregular holes, size deviation<0.002mm

Continuous automatic threading, achieving unmanned operation

China First Exhibition

New generation five axis horizontal machining center a800Z

The newly upgraded HSK-A100 spindle significantly improves the start stop efficiency of the spindle

The design of the Z-shaped workbench takes into account the rigidity and flexibility of the machine tool

All stainless steel vertical wall processing room design to reduce chip accumulation

Cooling design for main moving components such as turntable, spindle, and screw, ensuring excellent thermal stability

Can achieve hybrid flexible line integration with horizontal four axis a81nx

Horizontal machining center JA6

Large diameter lead screw

Roller guide rail

High performance and efficiency, suitable for processing high-yield parts

Multiple innovative technologies reduce cycle time by 20%

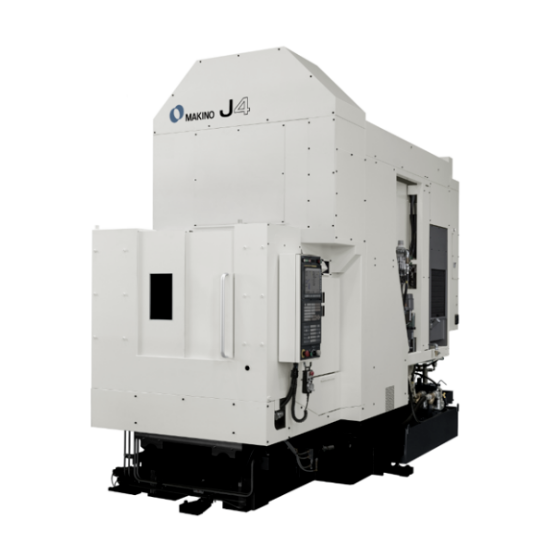

Five axis horizontal machining center J4

HSK-A63 spindle, maximum speed 14000 min-1

Maximum torque of 250 N · m, achieving high capacity machining of cast iron parts

Reduce the cost of mass production and processing

Can be combined with robots or gantry robots to flexibly achieve unmanned operation of production lines

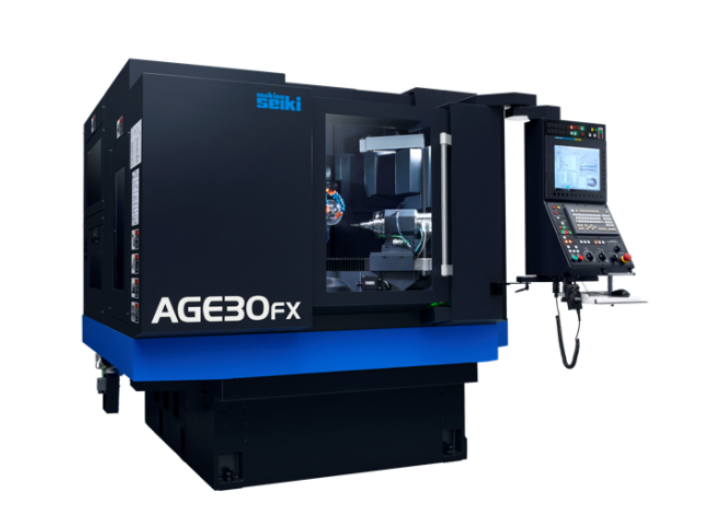

High precision CNC tool grinder AGE30FX

6-axis CNC control

X. Y, Z closed-loop grating ruler, A, W axis using DD motor, high-precision

High rigidity and high stability machine tool design, completely eliminating thermal deformation

Efficient automated processing

Applicable scope: φ 3~ φ High precision CNC tool grinding machine for producing 25 grade cutting tools